About Us

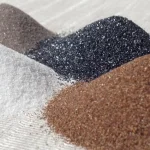

The company manufactures a range of Grit from mineral Copper Refinery Slag which converts itself into iron silicate during the smelting and quenching process in the copper smelter. The product is sold under the trade name of IRGRIT®.

IRAN GRIT. pjs® established in 2009, is a 100% private company with most reputed businessmen and business houses of Iran. Its shareholders are the ex-senior managers of National Iranian Copper Industries Co. (NICICO).

IRAN GRIT. pjs® is the sole copper slag grit manufacturer in the Middle East that has ISO 9001:2008 & 14001 certificate.

Product info

جامبو بگ های 2 تنی پشت تراک

کیسه لمینه 50 کیلویی مسباره براق

بسته بندی جامبو بگ 2 تنی

FAQ

Nozzle size should be in relation to the capacity of the compressor. Note that at continuous working the compressor should not run at more than 5% of the capacity.

Air Pressure at the nozzle should be between 80 and 100 psi (closer to 100 psi cause the better performance). Remember to achieve high nozzle pressure.

Avoid blasting perpendicular (90 degrees) to the surface. An angle of 75-80 degrees gives the best performance.

The air hose between compressor and blasting unit should be as large as possible and as short as possible.

The grit valve should be set at a lean feed. Too much grit in the air flow results in low production and less profile. Start with the grit valve closed, open gently until you get the proper effect and leave it there. The grit coming out of the nozzle should look like a blue haze and not like a black cloud.

Optimum distance between nozzle and surface is about 30 cm (12 inch).